2010

AMBATOVY SUSTAINABILITY REPORT

26

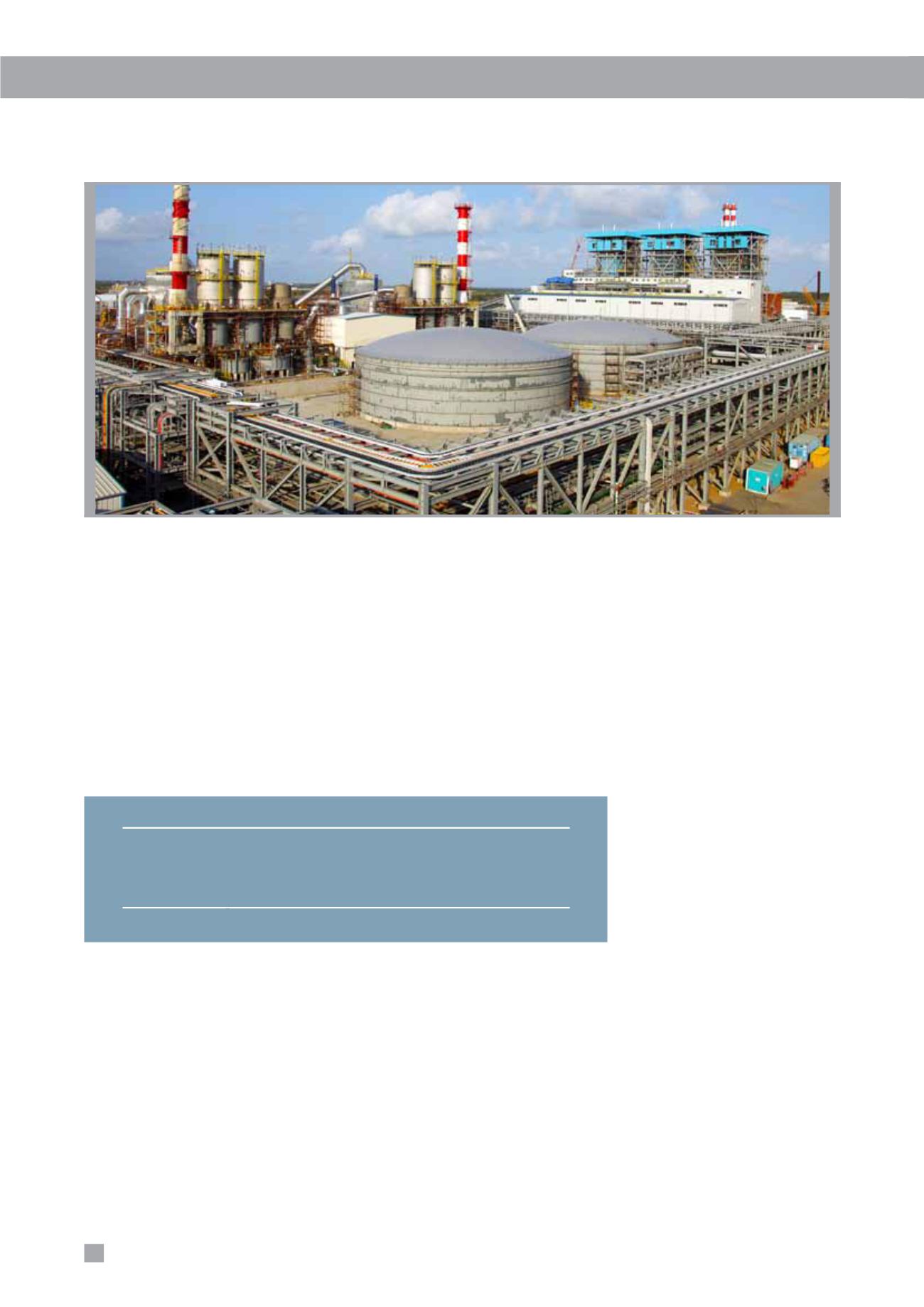

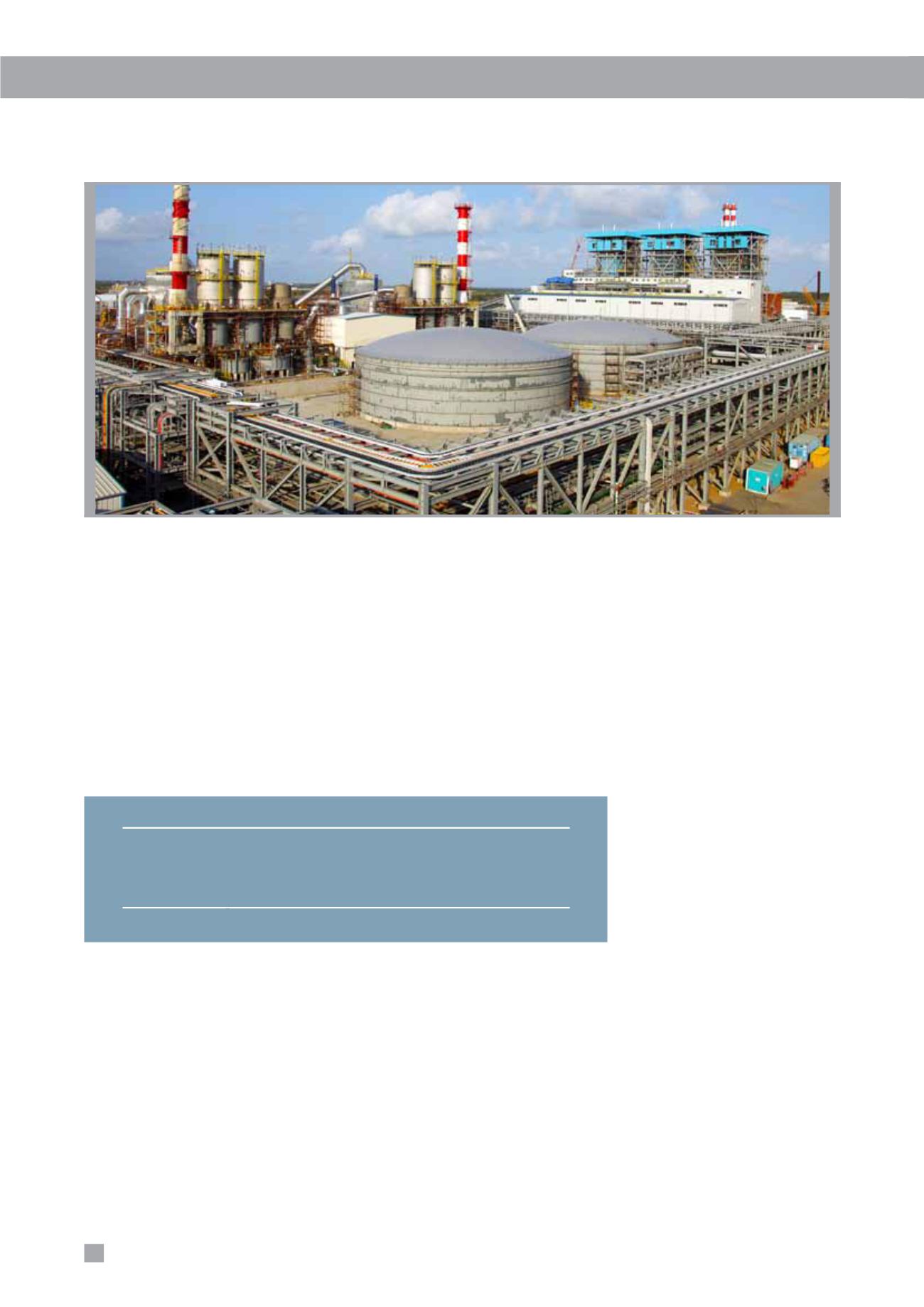

C1. Environmental Performance

Emissions

During the construction phase, emissions have been primarily

transport related. As operations begin, the balance will shift

strongly to emissions of greenhouse gases (GHGs) from

industrial operations, most of which would be attributed

to the generation of power and the use of limestone. The

management of GHG will be through operations efficiencies.

The plant site, for example, was designed to minimize

emissions to meet criteria stipulated by local regulations or

the IFC, and sometimes both. We will calculate and report

on an annual basis what our GHG emissions are, per our

management plans.

Reduction Initiatives

The plant design incorporates in-country processing coupled

with newer technology for maximum efficiency. The facility

is designed to be efficient from the start. Emission control

systems include:

3

Electrostatic precipitators on power plant emissions

3

Capability to add lime to the power plant emissions to

reduce sulphur dioxide (SO

2

) emissions

3

Scrubber systems to avoid ammonia and hydrogen

sulphide emissions

3

Flares to eliminate ammonia and hydrogen sulphide

releases

3

Oil separation systems to avoid oily water discharges

Ozone-Depleting and Other Emissions

Ambatovy has equipment in place to monitor all emissions

once operations begin. A small proportion of emissions will

comprise CH

4

and N

2

O. This quantity can be converted into

carbon dioxide equivalent (CO

2

e).This amounts to less than

1% of total emissions.

Air Quality

Ambatovy is conscious of the potential impacts that its

operations may have on the surrounding atmosphere and

therefore takes great care to ensure that all applicable

regulations with respect to air quality

are properly followed.

During construction and operations,

some air and noise emissions will

be generated by equipment and

machinery (boilers, pumps, fans,

machinery, etc.) and there will be

increased traffic flow on access

roads around Project sites. A noise-

monitoring program has been

established to measure and mitigate potential impacts on

human health and the surrounding wildlife.

Comprehensive monitoring of air quality, particulate matter

and dust emissions at the mine and plant sites will be

evaluated on an ongoing basis. The monitoring system is

based on international standards and includes measurement

of pollutants, sampling methods as well as meteorological

data analysis. Air quality monitors have been installed

within the perimeter of the mine and plant sites and provide

continuous monitoring of ambient air. These monitors

measure nitrogen dioxide (NO

2

), sulphur dioxide (SO

2

),

particulate matter and total dust.

Table 3: Total Emissions in Tonnes from Construction Fuel Consumption during 2010

GHGs

DMSA AMSA

Carbon dioxide (CO

2

)

40,385.3 41,4990

Methane (CH

4

) as volatile organic compounds carbon dioxide equivalency

37.3

38.3

Nitrous oxide (N

2

O) as NOx carbon dioxide equivalency

376.0

386.4

Subtotal emissions CO

2

40,798.6 41,923.7

Total emissions CO

2

for Ambatovy during 2010

82,722.3